海陸風電綠能源 熱像監測護安全 國研院儀科中心開發遙測技術加值風力發電

中華民國 109 年 1 月 24 日新聞資料

發展風力發電是政府重要能源政策。國家實驗研究院台灣儀器科技研究中心 (國研院儀科中心) 2019 年成功開發出應用於大型風力發電機的安全性監測技術,可運用遙測方式即時監控大型海陸域風機運轉狀態,提供產業界風機運轉後營運維護之重要依據。

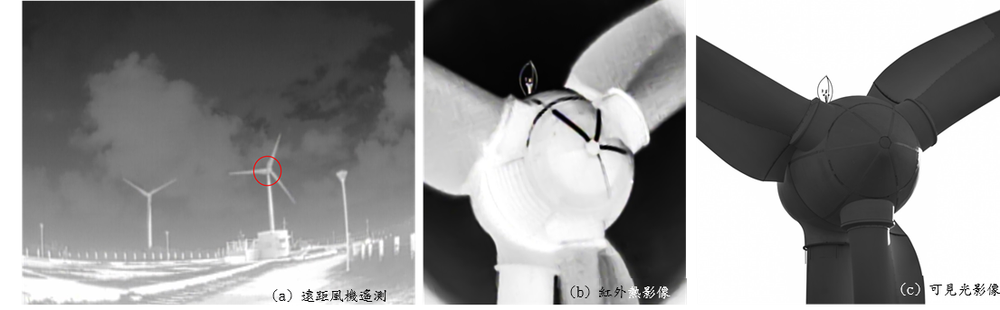

國研院儀科中心開發的監測儀器,係整合高解析紅外熱影像感測器與光學望遠鏡系統,可以進行視距外 (約 1.5 公里) 的海陸域風力發電機運轉安全性監測,提供早期損壞預警及老化程度之初判。目前已以苗栗後龍好望角風機機組完成監測系統的實地測試,確認可因應實際監測應用需求。

台灣海峽擁有良好的風力資源,為因應未來國內能源需求,發展大型海陸域風力發電技術,是解決未來能源短缺的重要科技之一。未來離岸風機位處於大海中,若以早期安裝感測器的方式,其電路後續保養及維修均不容易,若停機檢查則勞神傷財,因此難以長期經濟地監測風力發電機運轉效能與安全性。故發展新型態遠距離非接觸式的即時監測預警系統,是成功發展離岸風機系統的重要關鍵技術。

風機就像是一座小型的發電廠,當風驅動風機葉片旋轉時,會帶動機艙內的齒輪箱轉動,也因此各個零組件及葉片結構的健康狀態監測相當重要。當含有鹽分及細小沙礫的海風摩擦撞擊轉動中的葉片,就會導致孔蝕與裂痕,時間一長,原本光滑的葉片表面開始變得粗糙;一旦摩擦力增加,葉片上的玻璃纖維就會逐漸剝落,其損耗或老化初期都會導致風力發電效能降低;若未積極處理,更可能產生結構性的破壞而導致風機毀損。

紅外熱影像係非接觸式感測技術,具有快速、準確及可直觀顯示待測物體表面溫度場分布的特點,因此常應用在近距離的工業檢測領域上,量測高溫或難以接觸的元件表面溫度。國研院儀科中心將高解析紅外熱影像感測器整合光學望遠鏡系統,遠距拍攝風機葉片的紅外熱影像,提供整體結構表面的熱影像狀態。當風機葉片結構表面發生破損時,其熱輻射分布會與未破損時不一樣,易於發現裂痕及開口等表面缺陷;此外,葉片結構在振動頻率較高處,容易產生較高的熱輻射散失,輔以連續監測的溫度變化影像,即可進行安全性監測評估。與傳統鋪設單點或多點變形監測系統相較,這種二維影像的全面監測可以達到事半功倍的效果。

目前風力發電機設備仍需仰賴國外進口,但後續的維修支援應可成為台灣本土產業切入風電產業的突破關鍵。國研院儀科中心為執行衛星酬載計畫,長期發展遙測光電儀器技術,所建立的系統設計及組裝測試能量可應用於協助台灣廠商建立風力發電機即時監測預警系統,提高維修效率,降低維修成本,以技術扎根促進台灣風電產業的發展。

儀科中心開發應用於大型風力發電機之安全性監測儀器